charpy impact test specimen orientation|charpy impact test formula : tv shopping The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This . webDescubre la moda femenina de alta calidad de Daniel Cassin®. Diseñada para la mujer activa y moderna, nuestras prendas combinan estilo urbano, simple y moderno para que te sientas cómoda y elegante en cualquier ocasión. ¡Visítanos y descubre por qué somos líderes en el mercado textil de ropa para mujer!

{plog:ftitle_list}

"CSI: Crime Scene Investigation" is a fast-paced drama about a team of forensic investigators trained to solve crimes by examining the evidence. They are on the case 24/7, scouring the scene, collecting the irrefutable evidence and finding the missing pieces that will solve the mystery.

The dependence of the mechanical properties respect to the microstructural orientation of a low carbon steel API-5L grade X46 pipe was assessed by Charpy impact and tensile strength tests,.In Charpy testing a notched bar sample is loaded typically at high strain rates (3-6 m/s) over a range of test temperature. The samples are generally prepared along T-L orientation. The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This .The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum .

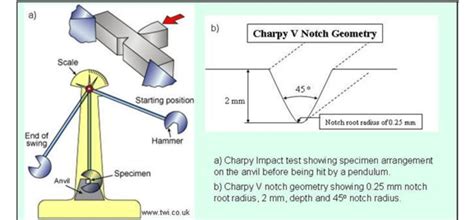

The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load [10]. This test consists of striking a suitable specimen with a .The Charpy impact test. The standard Charpy test uses a 10 mm × 10 mm specimen with a 2 mm deep V notch, placed upon an anvil and broken by a pendulum weight. The energy .

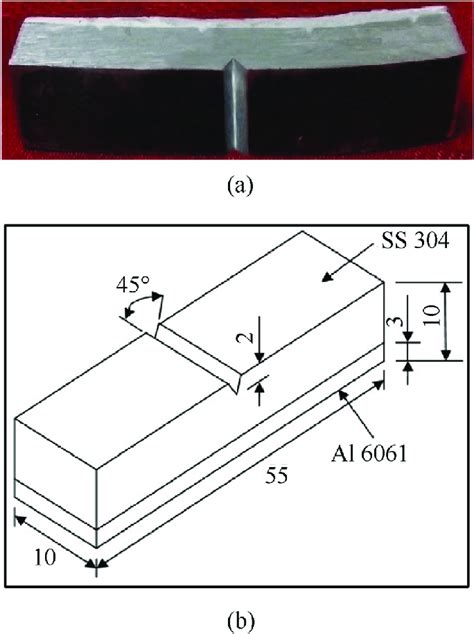

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's . standard specimen dimensions for Charpy impact tests of metals are comparatively small (10 by 10 by 55 mm with 40 mm span) [26,32]. The relative .

charpy v notch sample size

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .The specimen (and therefore the notch) orientation with respect to the plate rolling direction is significant. For rolled products, there can be a difference in impact properties between specimens notched parallel or transverse to the rolling direction. . The appearance of failed Charpy test specimens is also used to generate a ductile-to . While various methods are available to test for impact strength, the Charpy method of determining impact resistance of notched specimens of plastics (ASTM D6110-10) will be used for this experiment. The impact frame .

Charpy specimen was tested for each orientation condition. . In this paper, the geometry of standard Charpy impact test is designed. Specimens with different widths and side grooves are tested .

Switching gears, enter the Charpy impact test. This time, the specimen lies horizontal, chilling until a pendulum swings down to meet it. Think of it as the material’s rite of passage, testing its mettle (sometimes literally) against the merciless swing of the pendulum. . Izod Test Charpy Test; Orientation: Vertical: Horizontal: Notch .Charpy Impact Test: In this method, a test specimen is held at one end and struck on the opposite end with a pendulum hammer. The amount of energy absorbed by the specimen during fracture is measured. Izod Impact Test: This test method is similar to the Charpy impact test, but the specimen is held vertically, and the hammer strikes the specimen on the same side .Download scientific diagram | Schematic drawing of the orientation notch specimens from publication: Evaluation of delamination mechanisms from Charpy impact test in API-X70 steel | In this .Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. . including the shape and orientation of the specimen, which is clamped into the apparatus vertically with the notch facing .

The diagram below shows the grain direction for longitudinal and transverse charpy tests. If the grain direction for the charpy test is not in either of the orientations shown, but is instead coming out of the page (orthogonal to both orientations shown), would that also be classified as a transverse test or would it be something else?Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps. Parts printed at a 45° orientation demonstrated superior mechanical strength to those printed at a 90° orientation. Lambiase et al. . showing a notched Charpy impact test specimen with a line-type fill pattern and a scan angle orientation of 0°. The test specimens were fabricated using the Creality Ender-3 S1 Pro (Shenzhen, China) FDM 3D .

A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . Small changes in initial drop height, test specimen preparation, and test specimen orientation can drastically impact testing results. Test machine . It acts as an immovable surface against which the pendulum strikes after impacting the test specimen. 3. Test Specimen: The test specimen refers to the material being evaluated for its impact toughness. It is placed along with precision notches or grooves in between the anvils before initiating the test. The Testing Process. Understanding how a .In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.

A pendulum is released to strike the specimen. The height of the pendulum before and after passing through the sample is used to calculate the energy absorbed during the fracture process. For ductile materials, the test .

test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is . such as the anisotropy and the orientation can be studied by means of tensile impact test. It exist two different test configurations. One consists in a specimen-in-head kind of setup (method B), where the . The Charpy impact test has .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away . It acts as an immovable surface against which the pendulum strikes after impacting the test specimen. 3. Test Specimen: The test specimen refers to the material being evaluated for its impact toughness. It is placed along with precision notches or grooves in between the anvils before initiating the test. The Testing Process. Understanding how a . The hot-press-forming (HPF) steels might contain a few MnS inclusions, and their brittle characteristics and stringer shape can deteriorate the impact toughness and formability. In this study, effects of shape and orientation of MnS particles on Charpy impact and bending properties of 1470-MPa-grade HPF steel sheets were investigated by conducting ex situ three .

The Charpy impact test relies on the potential energy of a . length, and orientation of the fibers. The fiber orientation is im-portant in two senses: (1) whether the fibers are oriented uni- . Radomski suggested that the minimum dimension of impact test specimens be no less than five times the nominal maximum ag-The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

charpy impact test sample dimensions

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.

The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. These specifications have a very tight tolerance because the shape and size of the notch can have a significant effect on the results of the test.Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). This paper presents experimental results of standard three-point bending tests, for fused deposition modeling (FDM) specimens made of acrylonitrile–butadiene–styrene (ABS), as well as ABS plus. Both types of specimens were built with different building strategies. Furthermore, specimens of the aforementioned materials were subjected to standard .

Hazra et al. [20] have evaluated the forge effect of DDFW for high nitrogen steels and have concluded tensile and Charpy impact test results indicated that the joint strength is decreased with an . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

karl fischer titration coulometric volumetric distributor

charpy impact test sample

The objective is to defeat a horde of zombies, after a specified amount of zombies has been killed you get a supply drop that spawns randomly, it consists of a healthpack, ammo and 2 soldiers to add to your army. This gamemode contains .

charpy impact test specimen orientation|charpy impact test formula